Hot Runner Coil Heater

We are a professional manufacturer, supplier, and exporter that is concerned with the design, development, and production of Hot Runner Coil Heater. With convenient transportation access selling well throughout the domestic market, our products have won praise from customers worldwide, and are also warmly welcomed by clients in Taiwan. We are looking forward to cooperating with more clients worldwide for common development and mutual benefits. Contact us today to benefit from what we offer.

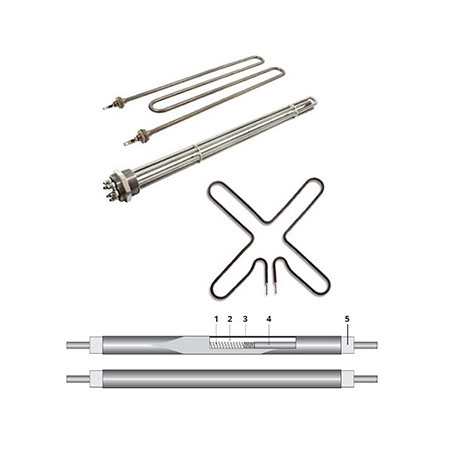

Hot Runner Coil Heater

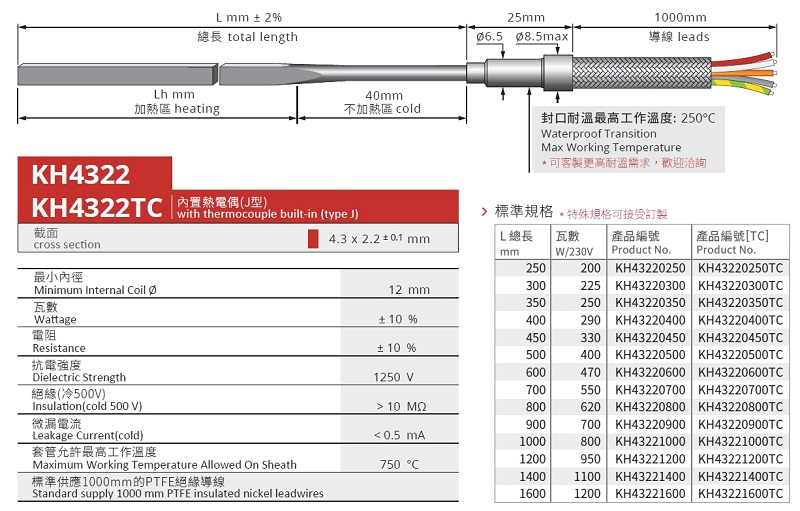

Model - Minitubular Heater KH4.3X2.2

- NiCr80/20 resistance wire

- High purity compacted magnesium oxide

- CrNi steel or SUS310 or SUS321 steel sheath

- Built-in thermocouple type J

- Tig welded bottom disc

- PTFE insulated nickel leadwires

Introduction

Apply solutions to difficult requirements, possible to work under high working temperature and limited spaces.

Can manufacture to different lengths, wattages, sections, and built-in J or K type thermocouples according to needs.

Applications

Hot Runner Systems

Plastics Industry

Engineering Industry

Shoe Industry

Home appliance technology

Casting Industry

High Vacuum Aapplications

Packaging Machines

Technical Data

We can support new designs according to the requirements of customers; our

Hot Runner Coil Heater

is to fulfill our potential to ensure the highest quality service. For more information on our products, please take your time to browse through our website or give us a call, we wish to be of service soon.Enquiry Now

Products List

NiCr 80/20 resistance wire

High purity compacted magnesium oxide

Nickel or stainless steel sheath

PTFE insulated nickel leadwires

Introduction

A solution to the most difficult requirements, possible to work under high working temperature and limited spaces.

Used for the best performance and various applications.

Applications

Used in the plastics industry for the heating of nozzles and hotrunner tooling.

Generally applied on where space is restricted.

Technical Data

NiCr 80/20 resistance wire

High purity compacted magnesium oxide

CrNi steel or SUS310 or SUS321 steel sheath

Built-in thermocouple type J

Tig welded bottom disc

PTFE insulated nickel leadwires

Introduction

A solution to the most difficult requirements, possible to work under high working temperature and limited spaces.

Can manufacture to different lengths, wattages, sections, and built-in J or K type thermocouples according to needs.

Applications

Hot Runner Systems

Plastics Industry

Engineering Industry

Shoe Industry

Home appliance technology

Casting Industry

High Vacuum Aapplications

Packaging Machines

Technical Data

NiCr80/20 resistance wire

High purity compacted magnesium oxide

Stainless steel sheath

Solid stainless steel terminal

Ceramic end cap

Introduction

Capable of being formed into virtually any configuration.

The range of ratings, sizes, materials and terminations available makes the tubular heater adaptable to many industrial, commercial, and scientific applications.

Applications

Used in pastics industry for the heating of Hot runner manifold plates tooling.

Flexbile Heaters enables heat to be located directly to the resin flow path with three dimensional heat distribution.

Technical Data

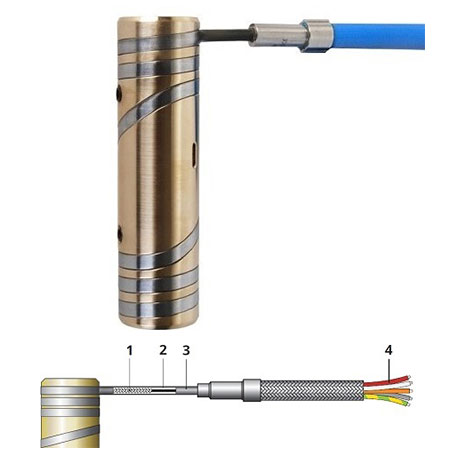

NiCr80/20 resistance wire

High purity compacted magnesium oxide

CrNi steel or SUS321 steel sheath

PTFE insulated nickel leadwires

Introduction

much uniformed heating conductivity and better fitting with tools for advanced appliances.

Several lengths, wattage, Inner and outer diameters can be supplied.

Applications

Specialized in Plastic Industrial nozzles and hot runner components,

prioritized under limited space.

Technical Data

Stainless steel clamping band

Mica insulation

NiCr alloy

Aluminized steel

Fiberglass insulated lead wire (Axial exit)

Introduction

Mica insulated band heater can perform at higher operating temperatures.

Long-live and efficient band heater is the key for high productivity of plastic extruders, injection and blow molding machines.

Applications

Used in the pastics industry of plastic extruders, injection and blow molding machines.

prioritized under limited space.

Technical Data

Silicone-rubber insulating layer

Heating resistor

Insulated lead wire

Introduction

The light and easy-to-shape silicone rubber material is used as the external heat-resistant insulating layer, which has fast, uniform heating, and high thermal efficiency features. It can be widely used as it can be customized to a variety of shapes.

Applications

Plastics Industry

Engineering Industry

Shoe Industry

Home appliance technology

Packaging Machines

NiCr80/20 resistance wire

High purity compacted magnesium oxide

Nickel or stainless steel sheath

PTFE insulated nickel leadwires

Introduction

Easy to assemble, economical solutions for the hot runner nozzle.

The coiled and pressed clamp heater ensures best heat contact with the nozzle.

The coiling is precisely designed to suit specific heat requirements.

Technical Data

English

English Français

Français Deutsch

Deutsch Русский

Русский Português

Português Italiano

Italiano हिन्दी

हिन्दी Español

Español 한국어

한국어 العربية

العربية Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Bahasa Indonesia

Bahasa Indonesia 日本語

日本語 Türk

Türk 繁體中文

繁體中文