Heating Rod

THOMAS CO., LTD. is one of the renowned names of Taiwanese manufacturers, suppliers, and exporters with a comprehensive range of Heating Rod. To ensure the quality of our products, we manufacture this utilizing high-grade material, which we procure from certified vendors. We provide these products with different gradations in size and specifications customizable as per the client's exact needs. Our range is in high demand by our clients spread across the international market and can be availed at industry leading prices.

Heating Rod

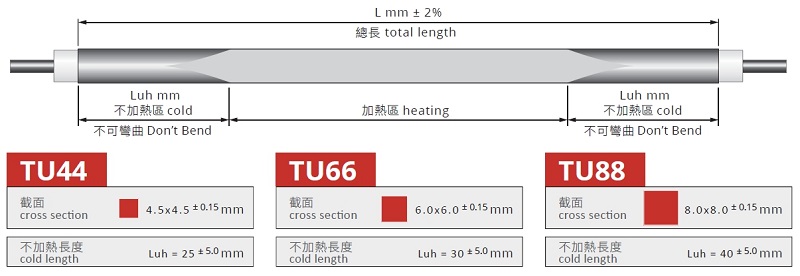

Model - Tubular Heaters

- NiCr 80/20 resistance wire

- High purity compacted magnesium oxide

- Stainless steel sheath

- Solid stainless steel terminal

- Ceramic end cap

Introduction

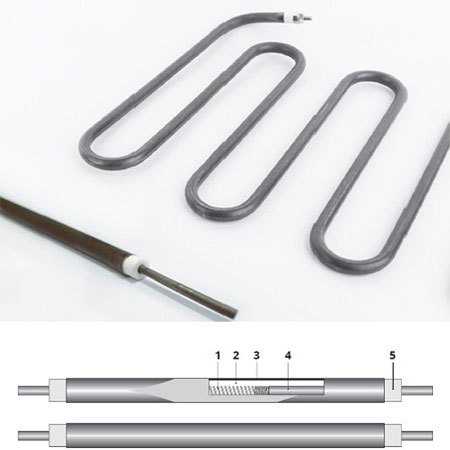

Capable of being formed into virtually any configuration.

The range of ratings, sizes, materials and terminations available makes the tubular heater adaptable to many industrial, commercial, and scientific applications.

Applications

Used in the pastics industry for the heating of Hot runner manifold plates tooling.

Flexbile Heaters enables heat to be located directly to the resin flow path with three dimensional heat distribution.

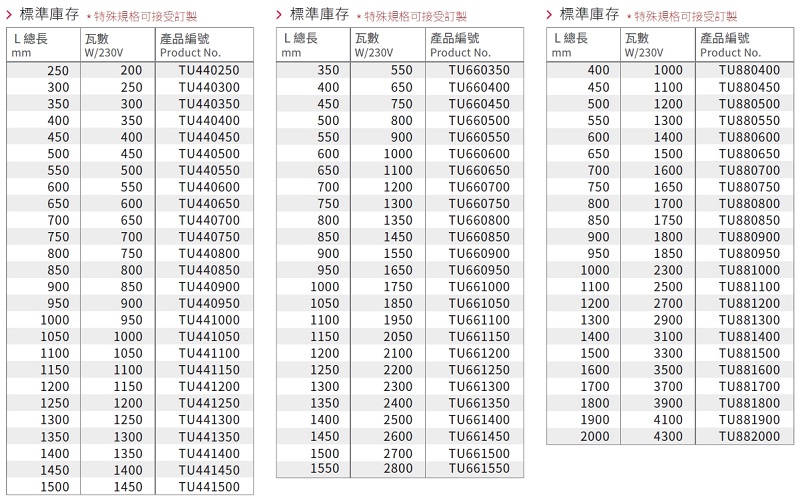

Technical Data

With advanced science and technology, our company develops and manufactures various kinds of

Heating Rod

. We offer the entire range in several standard options as well as useful customized choices to meet the specific demands of clients. Our products are at par with industrial quality standards.Enquiry Now

Products List

NiCr 80/20 resistance wire

High purity compacted magnesium oxide

Stainless steel sheath

Solid stainless steel terminal

Ceramic end cap

Introduction

Capable of being formed into virtually any configuration.

The range of ratings, sizes, materials and terminations available makes the tubular heater adaptable to many industrial, commercial, and scientific applications.

Applications

Used in the pastics industry for the heating of Hot runner manifold plates tooling.

Flexbile Heaters enables heat to be located directly to the resin flow path with three dimensional heat distribution.

Technical Data

NiCr 80/20 resistance wire

High purity magnesium oxide core

High purity compacted magnesium oxide

Stainless steel sheath

Ceramic end cap

Solid nickel conductors

Fiberglass-silicone insulated nickel leadwires

Tig welded bottom disc

Introduction

Computer generated manufacturing specifications, Nickel-Chromium resistance wire precisely wound on a Magnesium oxide core ensures efficient heat transfer.

Heavy wall sheath provides maximum protection against high temperature oxidation and corrosion.

To ensure heaters' lifespan: The bottom slug is TIG welded to the sheath to exclude contaminates, high-density cap seals are in place to resist contamination, and used high purity swaged Magnesium oxide.

Applications

Hot Runner Systems

Plastics Industry

Engineering Industry

Shoe Industry

Home Appliance Technology

Casting Industry

High Vacuum Aapplications

Packaging Machines

Technical Data

Standard Metric Type

English

English Français

Français Deutsch

Deutsch Русский

Русский Português

Português Italiano

Italiano हिन्दी

हिन्दी Español

Español 한국어

한국어 العربية

العربية Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Bahasa Indonesia

Bahasa Indonesia 日本語

日本語 Türk

Türk 繁體中文

繁體中文