Heating Element Rod

THOMAS CO., LTD. was established to manufacture and supply a variety of Heating Element Rod. Well-trained and experienced engineers are dedicated to precision and work optimization to ensure all the products are delivered in high quality at a competitive price. We are confident that we can meet your exact requirements with a short lead time, stable quality, and a highly competitive price. If there is anything that you would like to know more about our products, contact us today!

Heating Element Rod

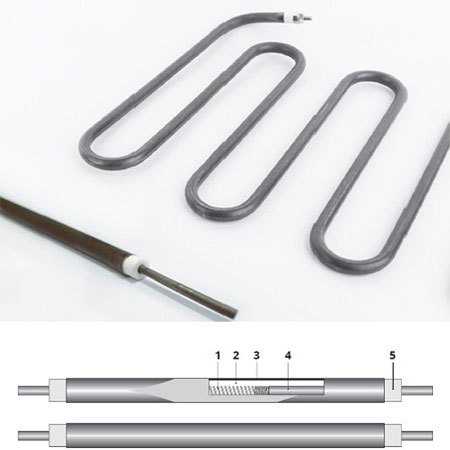

Model - Tubular Heaters

- NiCr 80/20 resistance wire

- High purity compacted magnesium oxide

- Stainless steel sheath

- Solid stainless steel terminal

- Ceramic end cap

Introduction

Capable of being formed into virtually any configuration.

The range of ratings, sizes, materials and terminations available makes the tubular heater adaptable to many industrial, commercial, and scientific applications.

Applications

Used in the pastics industry for the heating of Hot runner manifold plates tooling.

Flexbile Heaters enables heat to be located directly to the resin flow path with three dimensional heat distribution.

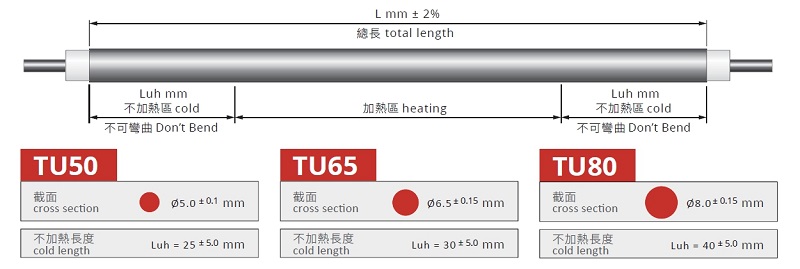

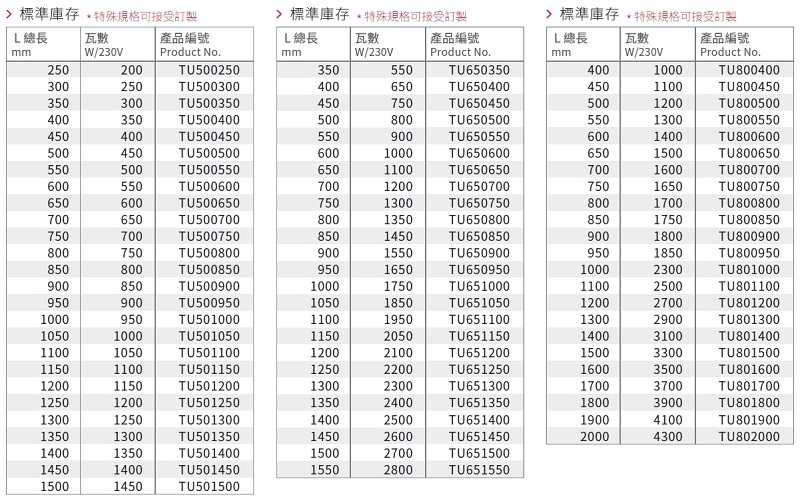

Technical Data

Since we care about our customers as we care about ourselves, our company puts plenty of effort into developing new items. Up-to-date technology will make our

Heating Element Rod

more perfect and make our life more colorful. Once you need it, we are here for you.Enquiry Now

Products List

NiCr 80/20 resistance wire

High purity compacted magnesium oxide

Stainless steel sheath

Solid stainless steel terminal

Ceramic end cap

Introduction

Capable of being formed into virtually any configuration.

The range of ratings, sizes, materials and terminations available makes the tubular heater adaptable to many industrial, commercial, and scientific applications.

Applications

Used in the pastics industry for the heating of Hot runner manifold plates tooling.

Flexbile Heaters enables heat to be located directly to the resin flow path with three dimensional heat distribution.

Technical Data

NiCr 80/20 resistance wire

High purity magnesium oxide core

High purity compacted magnesium oxide

Stainless steel sheath

Ceramic end cap

Solid nickel conductors

Fiberglass-silicone insulated nickel leadwires

Tig welded bottom disc

Introduction

Computer generated manufacturing specifications, Nickel-Chromium resistance wire precisely wound on a Magnesium oxide core ensures efficient heat transfer.

Heavy wall sheath provides maximum protection against high temperature oxidation and corrosion.

To ensure heaters' lifespan: The bottom slug is TIG welded to the sheath to exclude contaminates, high-density cap seals are in place to resist contamination, and used high purity swaged Magnesium oxide.

Applications

Hot Runner Systems

Plastics Industry

Engineering Industry

Shoe Industry

Home Appliance Technology

Casting Industry

High Vacuum Aapplications

Packaging Machines

Technical Data

Standard Metric Type

English

English Français

Français Deutsch

Deutsch Русский

Русский Português

Português Italiano

Italiano हिन्दी

हिन्दी Español

Español 한국어

한국어 العربية

العربية Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Bahasa Indonesia

Bahasa Indonesia 日本語

日本語 Türk

Türk 繁體中文

繁體中文