Mold Date Stamp

THOMAS CO., LTD. specializes in designing and manufacturing a wide range of Mold Date Stamp to meet the demands of the international market. The entire production process is conducted under intense quality control measures; besides our ordinary products, OEM projects are welcome.

Our advanced technology and hard-working staffs ensure the competitiveness of our top-quality

Mold Date Stamp

. Meanwhile, customer satisfaction is our constant pursuit.Mold Date Stamp

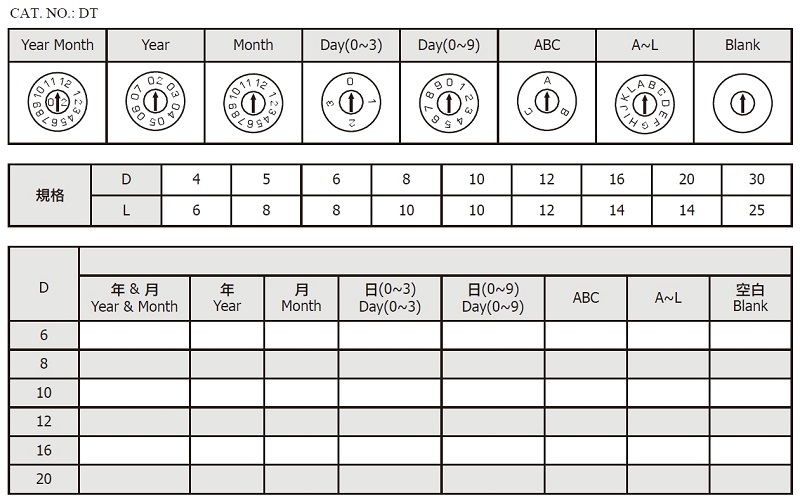

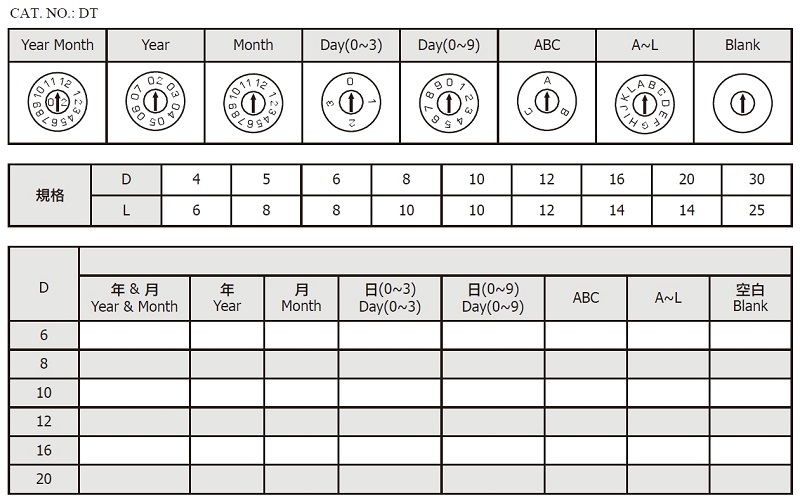

Model - DATE STAMP

MATERIAL: SUS420

SPECIFICATION:

CAUSION:

Technical Data

Mold Date Stamp – the essential tool for precision dating in your molding processes! Crafted with meticulous attention to detail, this stamp ensures accurate and reliable date markings, elevating the efficiency and traceability of your manufacturing operations.

Ideal for injection molding, die-casting, and various molding applications, our Mold Date Stamp guarantees clear and indelible date imprints on your products. Its durable construction and precision engraving make it an indispensable component for industries demanding accurate date identification, ensuring compliance and quality control.

Crafted from high-quality materials, our Mold Date Stamp is designed to withstand the demands of high-pressure molding environments, providing durability and extended lifespan. Its user-friendly design simplifies the dating process, catering to both seasoned professionals and those new to precision manufacturing.

Beyond its role in precise date marking, the Mold Date Stamp contributes to enhanced product traceability, compliance with regulatory standards, and overall operational efficiency. Elevate your molding processes, reduce errors, and invest in a stamp that not only streamlines the dating process but also optimizes the overall production outcomes.

Choose our Mold Date Stamp for a future where precision meets traceability. Upgrade your molding capabilities, enhance your date marking efficiency, and invest in a solution that not only simplifies the process but also elevates the performance of your entire manufacturing setup. Achieve precision and traceability with our Mold Date Stamp today!

SPECIFICATION:

- Outer case is made by stainless steel and with carbon treatment and grinding machining; reducing the chance of rusting to the least.

- Easy to install and very flexible.

- While rotating, it will be fixed and got ""TAI-TAI" noise.

- Improves the impression of the mold and the product.

CAUSION:

- Set-up with soft material such as copper or aluminum.

- Set-up mold not too tight, allowance around + 0.03mm.

- Do not disassembly unless necessary.

- Please arrange numbers on the same side.

Technical Data

Mold Date Stamp – the essential tool for precision dating in your molding processes! Crafted with meticulous attention to detail, this stamp ensures accurate and reliable date markings, elevating the efficiency and traceability of your manufacturing operations.

Ideal for injection molding, die-casting, and various molding applications, our Mold Date Stamp guarantees clear and indelible date imprints on your products. Its durable construction and precision engraving make it an indispensable component for industries demanding accurate date identification, ensuring compliance and quality control.

Crafted from high-quality materials, our Mold Date Stamp is designed to withstand the demands of high-pressure molding environments, providing durability and extended lifespan. Its user-friendly design simplifies the dating process, catering to both seasoned professionals and those new to precision manufacturing.

Beyond its role in precise date marking, the Mold Date Stamp contributes to enhanced product traceability, compliance with regulatory standards, and overall operational efficiency. Elevate your molding processes, reduce errors, and invest in a stamp that not only streamlines the dating process but also optimizes the overall production outcomes.

Choose our Mold Date Stamp for a future where precision meets traceability. Upgrade your molding capabilities, enhance your date marking efficiency, and invest in a solution that not only simplifies the process but also elevates the performance of your entire manufacturing setup. Achieve precision and traceability with our Mold Date Stamp today!

Enquiry Now

Products List

MATERIAL:SKH51

HARDNESS:HRC58°〜60°

Introduction

Locating ring is a part that is used for attach the injection center to the center of the mold quickly when installing a mold to the injection machine.

Usung the locating ring can significantly reduce the time it needs to match the mold to the machine and also reduce the chanceof damaging the machine.

Applications

The locating ring contains features such as high temperature resistance and wide variety of specifications. Other than using on locating the bush, locating ring can also be used to fix accessories.

Technical Data

BLOCK SET-BSD TYPE

MATERIAL:YK30

HARDNESS:HRC560〜600

MATERIAL:SKD11

HARDNESS:HRC58〜620

UNIT:mm, inch

BLOCK SET-BSG TYPE

UNIT:mm, inch

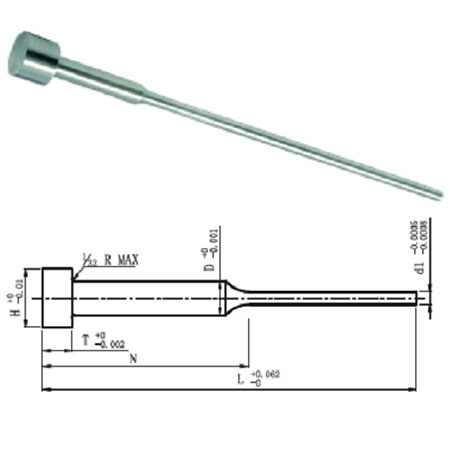

INCH STEPPED EJECTOR PIN

MATERIAL: SKD51

HARDNESS: HRC58°~ 62°

UNIT: inch

INCH EJECTOR PIN

MATERIAL: SKD51

HARDNESS: HRC40°~ 45°

SURFACE HARDNESS: HV900~

UNIT: inch

FLAT EJECTOR PIN

MATERIAL: SKD61

HARDNESS: HRC40°~ 45°

SURFACE HARDNESS: HV900~

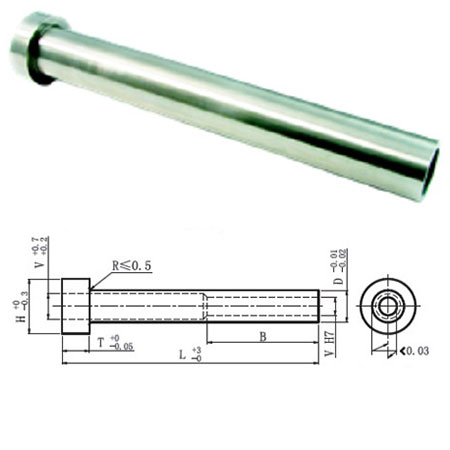

EJECTOR SLEEVE

MATERIAL: SKD61

HARDNESS: HRC35°~40°

SURFACE HARDNESS: HV900 ~

CAT. NO.: ES-D1

STEPPED EJECTOR SLEEVE

MATERIAL: SKD61

HARDNESS: HRC35°~40°

SURFACE HARDNESS: HV900 ~

INCH EJECTOR SLEEVE

MATERIAL: SKD61

HARDNESS: HRC35°~40°

SURFACE HARDNESS: HV900 ~

UNIT: inch

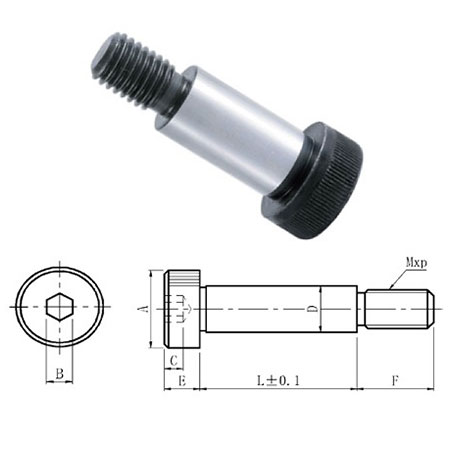

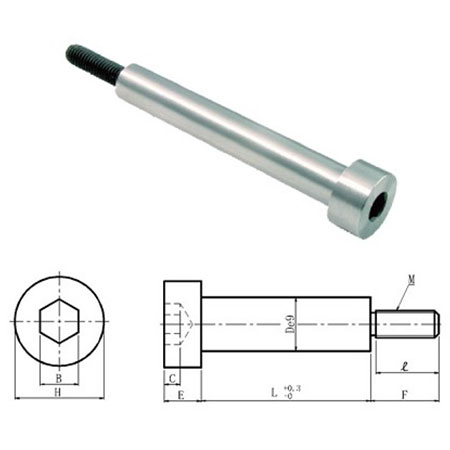

GUIDE PIN - GPA TYPE

MATERIAL: SUJ2

HARDNESS: HRC58°~

CAT. NO.: GPA

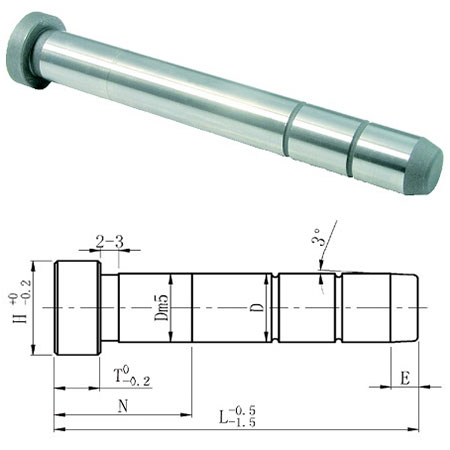

GUIDE PIN - GPB TYPE

MATERIAL: SUJ2

HARDNESS: HRC58°~

CAT. NO.: GPB

GUIDE PIN - GPB TYPE

MATERIAL: SUJ2

HARDNESS: HRC58°~

CAT. NO.: GPB

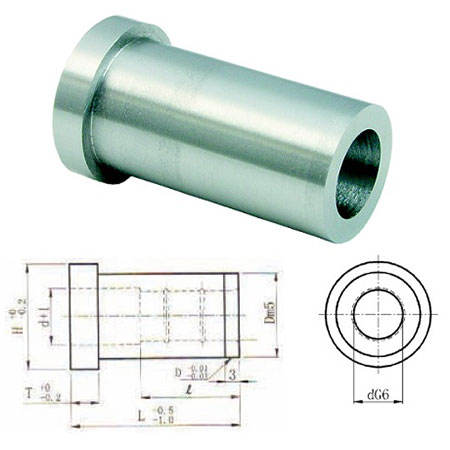

GUIDE BUSHING – (HEAD)

MATERIAL:SUJ2

HARDNESS:HRC58

CAT. NO.: GB-1

GUIDE BUSHING

MATERIAL: SUJ2

HARDNESS: HRC58°

CAT. NO.: GB-2

GUIDE BUSHING

MATERIAL: SUJ2

HARDNESS: HRC58°~

CAT. NO.: GB-5

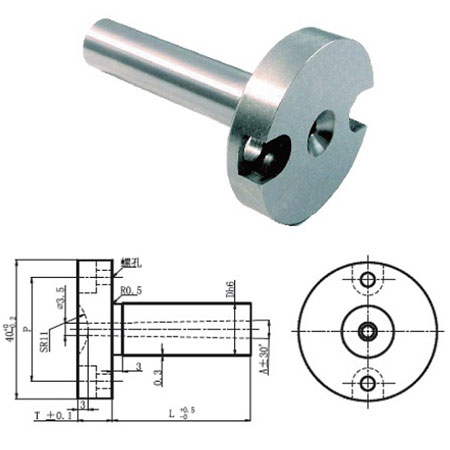

MATERIAL: SCM435

HARDNESS: HRC33°~38°

Technical Data

CAT. NO.: PBA

A cooling pin is a high speed heat transfer device capable of conducting heat energy over 1000 times faster than copper. It is made of a copper tube or chamber whose inner surface is lined with a copper wick structure.

The copper tube is sealed and the air is evacuated, creating a vacuum. When heat is applied to one end of the cooling pin by an external source, the internal working fluid dissipates as vapor. The resulting difference in pressure drives the vapor from the heated end to colder areas where it condenses and releases all the heat energy with a high degree of thermal uniformity.

Introduction

Reduce cycle time; uniform cooling improves part quality.

Special lengths available upon request.

1/2"

20 - 110 Nm

+3%

Introduction

1 CMKG = 13.883 IN-OZ

1 Nm = 8.8507 IN-LB

1 dNm = 0.0553 IN-OZ

1 MKG = 7.233 FT-LB

1 MKG = 9.80665 Nm 1 CMKG = 0.098 Nm

1 CMKG = 0.08677 IN-LB

1 KpM = 1 MKG

1 Nm = 0.73756 FT-LB

Applications

Always follow available manufacturer's specifications for fastener torque settings.

Any assembly held together by a number of fasteners (such as the lug nuts on an automobile wheel) should be tightened according to manufacturer's specifications. If no specifications are available, it is recommended that fasteners be tightened in two or more stages. For example, first tighten each faster to 75% of the total torque to be applied, then reset the wrench and tighten to the full torque required. Finally, double check each fastener to make sure none were missed.

Never use a torque wrench on a fastener that is already tightened with a standard wrench or pocket. For accurate torque readings, the fastener must be loosened, then retightened to the desired torque.

Cat. No.: PBC-

Protects metal parts from corrosion and seizure to 2012 F(1100C).

Capacity: 450g.

Introduction

The Anti-Seize Lubricant is an exclusively formulated colloidal copper compound primarily used on metallic surfaces .

It prevents seizing and galling caused by heavy loads, vibration, corrosion and temperatures up to 2012 F (1100C).

Can be used on most metals, including cast iron, steel, stainless steel, nickel, copper, brass, bronze, titanium, aluminum, and monel.

Applications

INSTRUCTIONS: STIR WELL BEFORE USING.

For best results, remove dirt, oil and grease first.

Apply Anti-Seize lubricant to parts that require protection.

Wipe away excess lubricant. Protection of parts is now assured.

Introduction

Pressure to air line of air poppet valve and machine ejection should be activated at the same time. This allows valve to relieve negative pressure build up (vacuum) in the cavity during part ejection.

The air flow to the poppet valve must be fully relieved to the atmosphere after each cycle to insure that the poppet valve closes before the next injection cycle. Material injected into a partially open poppet valve could cause damage to the valve and /or the mold. Control valves and limit switches to be supplied by moldmaker and / or molder.

The air poppet valve should never be used as the sole means of part ejection. Material shrinkage and other factors will not allow it to be used as an alternative to ejector pins or stripper plates.

Cat. No.: TP-

Class " B" Insulation.

1/2in. x 66ft. (22yds,) x .007in.

12.7mm x 20.1m x 0.18mm

Introduction

High-temperature tape with thermosetting pressure-sensitive adhesive.

Operates at Class B (266 F) temperature.

Provides heat-stable insulation for furnace, oven controls, motor leads, and switches.

Splice heat-resistant wires in "hot-spot" areas.

Applications

Before utilizing the product, the user should determine the suitability of product for its intended use.

3M expressly disclaims the implied warranties of fitness for a particular purpose.

In no case shall 3M be liable under any legal theory, including but not limited to contract or strict liability, for any direct, indirect, special, incidental or consequential damages resulting from product use.

Resist water and oil.

It can be used in various uneven surface.

Technical Data

Maximum: Operating temperature is 250℉.

Counter: Non-resettable mechanical, 6-digit.

Introduction

Counter housing panel can be marked for easy identification.

Assembled detail as shown above.

Counter with screws can fixed to the mold.

Technical Data

The main function of the counter is to calculate the number of finished product.

Able to maintain by mold cycle.

Improve production efficiency through digital management.

Material: Glass-filled Nylon housing

Maximum: Operating temperature is 250℉ (120℃)

Counter: Non-resettable mechanical, 7-digit

Introduction

Counter housing panel can be marked for easy identification.

Assembled detail as shown above.

Counter with screws can fixed to the mold.

Technical Data

The main function of the counter is to calculate the number of finished product.

Able to maintain by mold cycle.

Improve production efficiency through digital management.

English

English Français

Français Deutsch

Deutsch Русский

Русский Português

Português Italiano

Italiano हिन्दी

हिन्दी Español

Español 한국어

한국어 العربية

العربية Tiếng Việt

Tiếng Việt ภาษาไทย

ภาษาไทย Bahasa Indonesia

Bahasa Indonesia 日本語

日本語 Türk

Türk 繁體中文

繁體中文